A majority of woodworking projects require pieces of wood to be joined together somehow, and while glue and other adhesives are a fixing solution, most workpieces are better connected by a woodworking specific joint. There are quite a few common woodworking joints that you can invest in learning to add to your woodworking repertoire, and this will make future projects easier knowing you have an array of joints on hand ready to go.

All common wood joints are specific to the way they are utilised in woodworking, which is why it’s beneficial to have a good collection of joinery tools and accessories. When it comes to connecting two pieces of wood together with joints, you can simply use wood glue, brackets and screws, nails, dowels, or staples. Each joint has its own strength and advantage, when you become well enough versed in the world of wood joints, you’ll be able to turn to your equipment and grab exactly what you need.

Browse our range of woodworking products and other timber supplies online today or give us a call on 07 3266 9000 with any additional questions on common wood joints.

Common Wood Joints

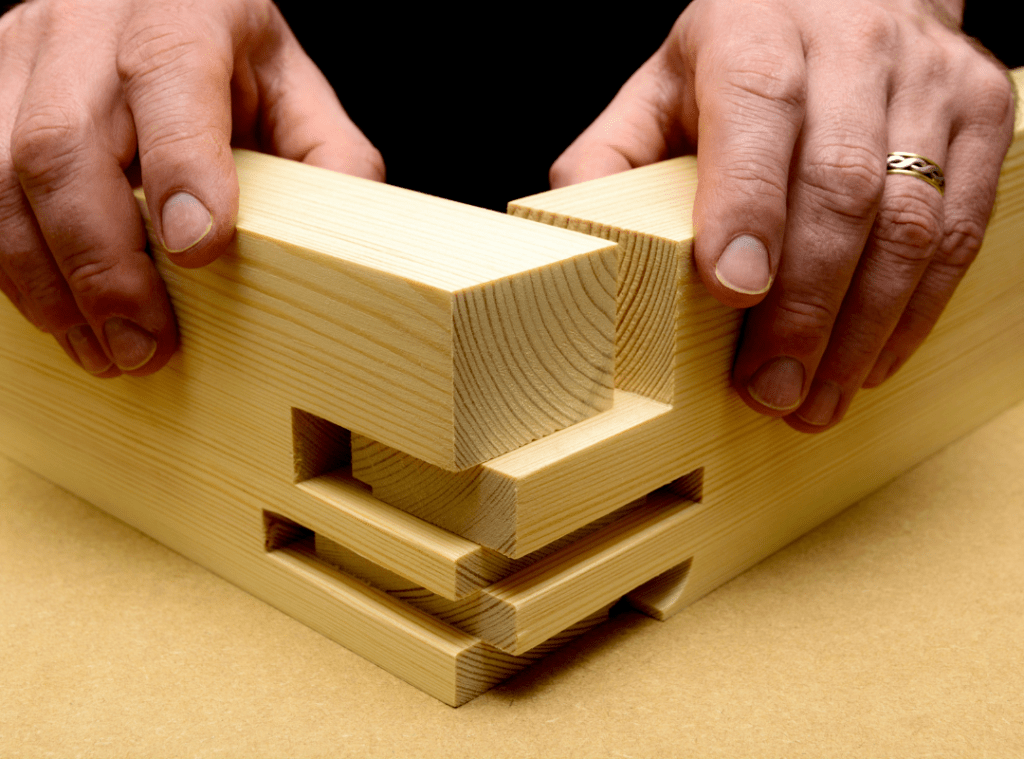

Box Joint

A box joint is one of the most common woodworking joints (among others) that is essentially made by cutting a set of interlocking profiles into two ends of wood, and then joined at right angles. The box joint is suitable for joining much rather slats, boards and solid wood panels together, interlocking and creating a solid hold.

Butt Joint

Common wood joints known as a butt joint is where one wooden piece is quite literally butted against another, typically two edges or faces. Although these joints aren’t necessarily the strongest of them all, they can be fixed together by glue blocks or with screws for extra structural support, creating a simple, seamless, and easy join.

Dowel Joint

Oftentimes some woodworking joints will require the use of dowel joints. This can be seen more so in the construction and installation of furniture. The ends of dowel joints are two wooden workpieces that are constructed with one or more hollow tubes that are essentially designed to support what is called a dowel pin. These are used in conjunction with a butt joint – they are joined at a right angle and then reinforced with one (or more, if need be) dowel pins.

Tongue & Groove Joint

One of the most common woodworking joints that you’ve probably heard of before is the tongue and groove joint. This is presented as a joint between two boards, one with a raised area in the middle of one board, and two corresponding edges on the other forming a slot – they then slot together perfectly to create a flush surface. This allows two flat pieces of wood to be joined strongly together.

Through Dovetail Joint

A through dovetail joint is where the end grain of both boards is visible where the joint is assembled – this creates a beautiful dovetail effect from all sides on the board (or box). This joint is known to be quite strong and is also sometimes referred to as lapped, English, or plain dovetail. These joints are most commonly used on box constructions, and carcass.

Contact Versace Timbers Today!

Looking for some more great ideas to lift your joinery common wood joint knowledge? Contact the team at Versace Timbers today on 07 3266 9000 and we’ll help answer any questions or provide more information. Additionally, you can reach out using our online form, or send us an email at [email protected] and we’ll be in touch.